|

PLEASE PATRONIZE OUR SPONSORS!

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

#11

|

|||

|

|||

|

JBrewer posted, "PS: What happens if you shoot a little gas into the carb throat and then crank...does it fire or no?"

Matt Gonitzke posted: "If you had it running its probably not a compression or ignition issue. Make sure it is getting gas and that the carb is set right. Try 2 1/8 turns on the main jet and 1 3/4 on the idle." I'll piggy-back on what JBrewer and Matt posted; if you had it running, what could have changed? When fixing starting problems, one must focus on the essential fundamentals: 1. Compression 2. Fire 3. Fuel The easiest way to eliminate or isolate ignition problems is to feed fuel directly into the carburetor, using either some gasoline, starter fluid, or carb cleaner (I use a short squirt of starter fluid). If it starts "on the juice" then the problem is fuel; if it doesn't start, there is an issue with the ignition. Given your situation, if it doesn't respond to the starter fluid, I would again follow JBrewer's advice and "lay plug on the head and look and listen while you crank." If you can see spark, then (and only then) you know that the ignition system is working and the problem is the timing. But for the engine not to even start, when you've got a spark and have given it fuel, there would have to be a serious problem with the timing, I would think. If you don't see a spark with the plug on the head, then you know to start investigating the ignition switch, grounds, condenser, coils, etc. The main thing is to not let the fact that the engine is not starting throw you into a panic. Think carefully, logically, and completely what could cause the symptoms you're see, which ONE THING makes the most sense to try first, what you expect to see as a result, and try it. After you see the results, and account for them, you can move on to the next item on the list. If all else fails, walk away from it; do something else, sleep on it and rising to a new day everything will become clear. |

|

#12

|

||||

|

||||

|

Based on your latest reply it sounds like you may not have it timed anywhere near correct, which would cause it to start hard and not have any power. Take off the flywheel shroud and find the marks, clean, and mark them so you can see them. They are there. Then find your multimeter and make sure the timing is correct before you do anything else.

|

|

#13

|

||||

|

||||

|

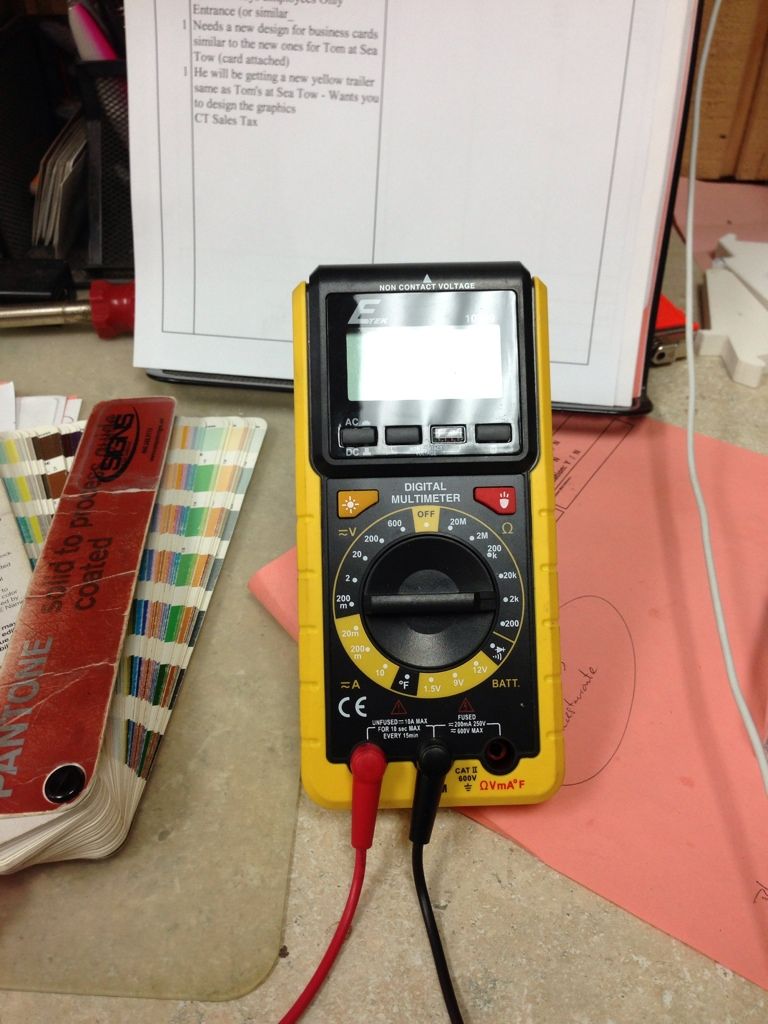

After dicking with the points for a while, i tried Matts Timing Method. My multimeter is digital and i could not tell when it was at zero ohms and infinite ohms. Attached is a pic of my multimeter (and what setting i had it on). i did find the notches on the flywheel. and tried my best to set the points. I set the points at .016, .020, .013 and a bunch of others. I could get it to run at .016 but it would only idle. then i changed it again and it wouldnt start at all.

This whole time i was cranking the motor over and thought i killed battery, went and bought a new one and then found that my starter wasnt cranking well (even with a 200amp jump start charger she wasnt cranking over well). so we took starter off and couldnt get it to spin well at all. so now i am taking that apart. i had a huge mouse nest in my flywheel and think there was mouse piss all over the brushes. I cant believe how expensive starters are, is there anywhere to get them for less money? Getting real frustrated, any help would be apprecitated. Need to get her going for winter snow plowing. Here is a pic of the multimeter. Is there another way to time the motor, i am having a real hard time getting it timed.

|

|

#14

|

||||

|

||||

|

It really doesn't make much of a difference which of the 'ohms' ranges you have it set on. The highest one would probably make the most sense. Put it on any ohms setting and touch the leads together. That is zero resistance (or near zero...most digital meters have internal resistance that shows up in the measurement and can't be adjusted out) and whatever the screen shows when the leads are not touching is open. It's very simple. Try again now that you know how to read the meter.

|

|

#15

|

|||

|

|||

|

Quote:

sounds like you have pulled the starter and took it to the bench. when you say not spinning well (don't think you needed 200a for that...10a works) I'd suspect brushes but perhaps the housing magnets are faulty. See what your 4 brushes and springs look like. The Kohler manual available here has a very good section on placement of the positives and grounds and also describes how to make a brush holding tool to get everything back together. If the magnets are still intact, I used Walmart rubbing alcohol to clean them and the internal guts (don't wear your Sunday church clothes for that operation). timing...I never have found the timing marks on my K341 and I simply set the points at .020 at their widest opening (wire gauge, not flat). A real pain given where they are and a rather primitive mounting/adjustment method that is like playing "whack a mole" but it works. the fact that it starts and idles but dies when under load...I've read here that the vibration can cause problems with a nicked ground wire from the points to the coil. But I'd suspect fuel related. Can you keep it running by manually goofing with the governor? |

|

#16

|

||||

|

||||

|

Kohlers don't spin over like a car...they turn over slowly. If it started before it should be good to go now. Don't change too much stuff at once or you're REALLY going to get frustrated.

The points reading should be just the same as touching the leads together, and then not If that results in a change of readings, you're using the meter correctly. IF there is actually no change, then you've got a wire shorted to ground, or perhaps a shorted condenser. Can you SEE the points opening when you turn the motor by hand? John

__________________

61 and 63 Originals 123 (2) 782D 106, 147, 122 102 parts It's only original ONCE!

|

|

#17

|

||||

|

||||

|

That meter has a continuity function that will beep when there is continuity. That comes in handy so you don't have to look at the meter and just listen for the beep.

__________________

This ain't no hobby....it's an addiction |

|

#18

|

|||

|

|||

|

Quote:

I'm only an amateur here but the fact that it dies under load suggests a carb and/or governor issue. I don't think a .01 or two or three on the point setting is going to be critical in keeping it running (may run "ugly" but it will run). Before embarking on that carb though, I would use a VOM on the coil to see if there isn't something going on when load is applied. Ideal situation would be a bad ground somewhere that only shows when the throttle is opened...doesn't take much time to correct). |

|

#19

|

||||

|

||||

|

Hey guys thanks for all your help. i have the brushes out of the starter and they are being cleaned up. Hopefully this does the trick.

So i get this straight, at this point if i get it running again (really it only idles) the rest should be adjustments of the carb? Is my problem the carb now? Here is a pic of a small bare spot in my ground to the block, could this be my problem? Should i change the condenser? Does that make a big difference?

|

|

#20

|

||||

|

||||

|

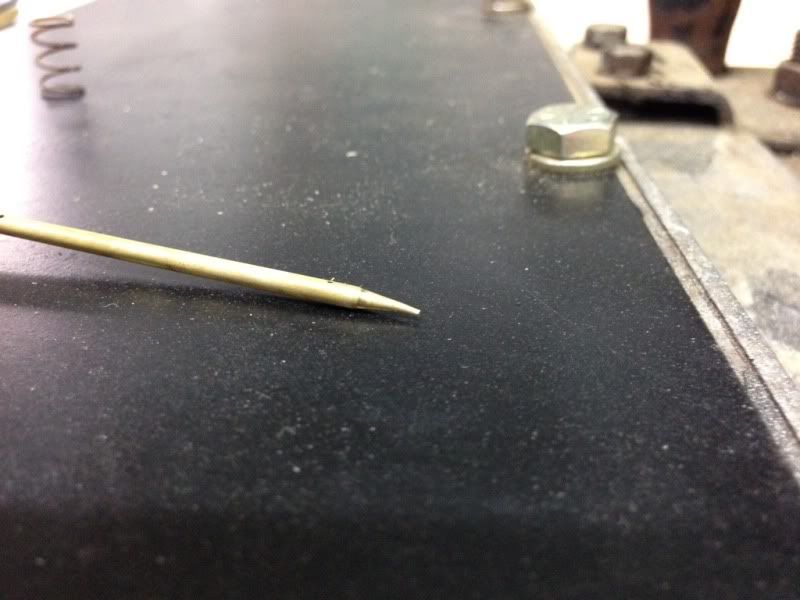

I just took my carb off again and found that the needle in the main jet is damaged a little (the point of the needle is bent a little)

__________________

1977 1450 Hydro -At the Shop! and a 582 Special on torn down on the bench. QA42A, 2 44 decks, snow blade, trailer. |

|

|

|

Cub Cadet is a premium line of outdoor power equipment, established in 1961 as part of International Harvester. During the 1960s, IH initiated an entirely new line of lawn and garden equipment aimed at the owners rural homes with large yards and private gardens. There were a wide variety of Cub Cadet branded and after-market attachments available; including mowers, blades, snow blowers, front loaders, plows, carts, etc. Cub Cadet advertising at that time harped on their thorough testing by "boys - acknowledged by many as the world's worst destructive force!". Cub Cadets became known for their dependability and rugged construction.

MTD Products, Inc. of Cleveland, Ohio purchased the Cub Cadet brand from International Harvester in 1981. Cub Cadet was held as a wholly owned subsidiary for many years following this acquisition, which allowed them to operate independently. Recently, MTD has taken a more aggressive role and integrated Cub Cadet into its other lines of power equipment.

This website and forum are not affiliated with or sponsored by MTD Products Inc, which owns the CUB CADET trademarks. It is not an official MTD Products Inc, website, and MTD Products Inc, is not responsible for any of its content. The official MTD Products Inc, website can be found at: http://www.mtdproducts.com. The information and opinions expressed on this website are the responsibility of the website's owner and/or it's members, and do not represent the opinions of MTD Products Inc. IH, INTERNATIONAL HARVESTER are registered trademark of CNH America LLC

All material, images, and graphics from this site are the property of www.onlycubcadets.net. Any unauthorized use, reproductions, or duplications are prohibited unless solely expressed in writing.

Cub Cadet, Cub, Cadet, IH, MTD, Parts, Tractors, Tractor, International Harvester, Lawn, Garden, Lawn Mower, Kohler, garden tractor equipment, lawn garden tractors, antique garden tractors, garden tractor, PTO, parts, online, Original, 70, 71, 72, 73, 76, SO76, 80, 81, 86, 100, 102, 104, 105, 106, 107, 108,109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 182, 282, 382, 482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 805, 882, 982, 984, 986, 1000, 1015, 1100, 1105, 1110, 1200, 1250, 1282, 1450, 1512, 1604, 1605, 1606, 1610, 1615, 1620, 1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812, 1912, 1914.