|

PLEASE PATRONIZE OUR SPONSORS!

|

|||||||

|

|

|

Thread Tools

|

Display Modes

|

|

#1

|

|||

|

|||

Having trouble removing the pto on my K321 which is in a CC149. Have all the allen screws out and it will woble but can get it to release from the bearing. The reason for removing is to replace the bearing. Any suggestions or ideas on removing the pto will be grealty appreciated. Thank you for your time. Having trouble removing the pto on my K321 which is in a CC149. Have all the allen screws out and it will woble but can get it to release from the bearing. The reason for removing is to replace the bearing. Any suggestions or ideas on removing the pto will be grealty appreciated. Thank you for your time.

|

|

#2

|

||||

|

||||

|

You do have all 6 set screws out correct? It will need to come out straight and not at any kind of an angle. Use some PB as well. Sometimes the clutch disk catch inside the basket too.

__________________

(2) Original, 100, 102, 124, 73, 800, #1 and #2 cart, brinly plows, disk, IH184, IH244, 1948 F Cub |

|

#3

|

||||

|

||||

|

You know there are two set screws in each hole, right? one on top of the other. Assuming you get all six out, here's what I do. I take about a 2 foot piece of 1x2 (hardwood like maple or cherry if you can get it). Then use that like a drift to "knock" the clutch off. Put one end in the pulley groove, find a direction (I usually work from the governor side) and lay the stick back against the block as far as you can. Then tap the end of the stick to drive the pulley (and clutch) off the bearing. Tap, rotate, tap, rotate, tap, rotate, tap a little harder if you have to...etc. until it come off. You are using the stick and a hammer to drive the clutch off, if that all makes sense.

Then you will need to remove the bearing....remove setscrews from the black eccentric locking collar behind the bearing, then using a punch, knock the black ring counter clockwise to loosen it. (usually it's counter clockwise, I had one that was the other way). Once the locking ring is loose, use a gear puller to pull the bearing off the shaft. the locking ring will come right off as well. Removing the clutch basket is a challenge. Remove the set screws, then, with a helper, using two long (3-4') wrecking bars/crow bars, get behind the basket as close to the shaft as you can, from opposite sides, and pry the basket off the shaft. Use heat on the basket if you have to. I've had to mount the block in a big woodworking vise or set in on a very sturdy workbench, and with the help of another person, both of us putting our considerable weight on the pry bars, to pop the basket loose. heat, a few hammer taps to the hub, and lots of penetrating oil can help. Good luck! PS, there is a good utube video that you might want to look at. search for cub cadet pto removal.

__________________

|

|

#4

|

||||

|

||||

|

Two in each of the three holes. Thread size is 1/4-20 NC and the hex wrench size is 1/8"

|

|

#5

|

||||

|

||||

|

Quote:

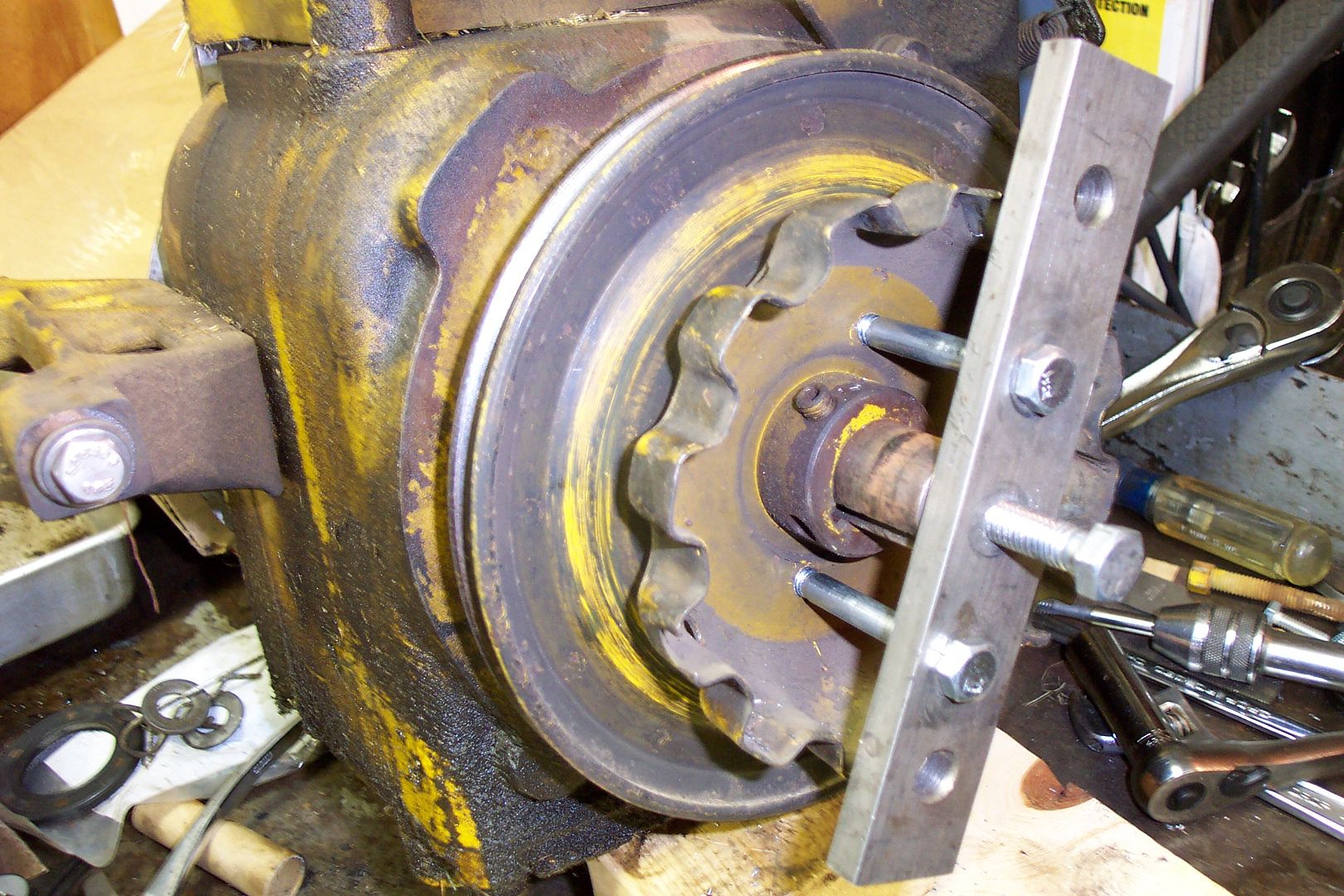

click for bigger pic |

|

#6

|

||||

|

||||

|

That's an elegant solution! I like that much better than brute force. I'll try that next time. Thanks for sharing, Jeff.

__________________

|

|

#7

|

||||

|

||||

|

Quote:

__________________

Daniel G.  . (May 1970) 147 w/an IH spring assist, 48" deck, 42" blade, 1969 73, #2 trailer, 10" Brinly plow and (on loan) Dad's #2 tiller. |

|

#8

|

|||

|

|||

Thank you everyone for your replies. I will take your suggestions/ideas an give it another go. Thank you everyone for your replies. I will take your suggestions/ideas an give it another go.

|

|

#9

|

|||

|

|||

Glad to report that the PTO has been removed and the bearing replaced. Used red oak dowel to force off. Thanks again everyone for the suggestions and advice. Glad to report that the PTO has been removed and the bearing replaced. Used red oak dowel to force off. Thanks again everyone for the suggestions and advice.

|

|

#10

|

||||

|

||||

|

Excellent news, good job.

|

|

|

|

Cub Cadet is a premium line of outdoor power equipment, established in 1961 as part of International Harvester. During the 1960s, IH initiated an entirely new line of lawn and garden equipment aimed at the owners rural homes with large yards and private gardens. There were a wide variety of Cub Cadet branded and after-market attachments available; including mowers, blades, snow blowers, front loaders, plows, carts, etc. Cub Cadet advertising at that time harped on their thorough testing by "boys - acknowledged by many as the world's worst destructive force!". Cub Cadets became known for their dependability and rugged construction.

MTD Products, Inc. of Cleveland, Ohio purchased the Cub Cadet brand from International Harvester in 1981. Cub Cadet was held as a wholly owned subsidiary for many years following this acquisition, which allowed them to operate independently. Recently, MTD has taken a more aggressive role and integrated Cub Cadet into its other lines of power equipment.

This website and forum are not affiliated with or sponsored by MTD Products Inc, which owns the CUB CADET trademarks. It is not an official MTD Products Inc, website, and MTD Products Inc, is not responsible for any of its content. The official MTD Products Inc, website can be found at: http://www.mtdproducts.com. The information and opinions expressed on this website are the responsibility of the website's owner and/or it's members, and do not represent the opinions of MTD Products Inc. IH, INTERNATIONAL HARVESTER are registered trademark of CNH America LLC

All material, images, and graphics from this site are the property of www.onlycubcadets.net. Any unauthorized use, reproductions, or duplications are prohibited unless solely expressed in writing.

Cub Cadet, Cub, Cadet, IH, MTD, Parts, Tractors, Tractor, International Harvester, Lawn, Garden, Lawn Mower, Kohler, garden tractor equipment, lawn garden tractors, antique garden tractors, garden tractor, PTO, parts, online, Original, 70, 71, 72, 73, 76, SO76, 80, 81, 86, 100, 102, 104, 105, 106, 107, 108,109, 122, 123, 124, 125, 126, 127, 128, 129, 147, 149, 169, 182, 282, 382, 482, 580, 582, 582 Special, 680, 682, 782, 782D, 784, 800, 805, 882, 982, 984, 986, 1000, 1015, 1100, 1105, 1110, 1200, 1250, 1282, 1450, 1512, 1604, 1605, 1606, 1610, 1615, 1620, 1650, 1710, 1711, 1712, 1806, 1810, 1811, 1812, 1912, 1914.